682 Commerce Parkway West Drive, Greenwood, IN 46143

Toll Free: 800.876.5340

Tel: 317.888.3002

Fax: 317.888.2335

Email: mail@dunhamrubber.com

The All In One Splice Press

The Aero™ Press is revolutionizing the splicing industry due to its ease of use and quick cycle time. This air cooled press has all components integrated into the tool, allowing a user to simply plug it into electricity and it is ready for use.

Efficient & Fast Splicing - All In One.

Once taken from the flight case the unit is fully operational and ready to splice. There are no external systems such as water tanks and pumps needed. All functions and subsystems are integrated into the press. The press has an integrated air-cooling system which ensures that the belt is quickly cooled down. This increases the splice quality and the operating speed of the press. For most belt materials, the entire operation can be completed within 7 to 12 minutes. This means a minimum interruption of the processes in which the conveyor bells are used.

Less Downtime - Splice in 7-12 minutes.

All-In-One Unit - No external components.

Integrated Air Cooling - No water required.

Portable Equipment - Flight case included.

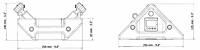

Aero™ Specifications

The Aero™ splice press is available in five different models ranging in width from 24" (300 mm) to 60" (1500 mm). The unit operates on most common voltages. The Aero™ splice press can be used for splicing PVC and polyurethane belt materials ranging in width from 1/2 - 60" (10 to 1524 mm) depending on the model.

Easy to operate and excellent splice repeatability

The Aero™ has two controllers. One for adjustment of temperature and time and one for setting the pressure generated by the built-in compressor. The material / splice specific pressure and temperature values are easily set and the splicing operation itself is fully automatic. The temperature controller has a scrolling display which navigates the user through the settings in clear text messages.

With two quick-clamping bars it is easy to position and fasten the material in the press. The clamping bars ensure that the material remains in position during the entire splicing process.

Temperature control and cooling

With the Aero™ press, the user can set different splice temperatures for the upper and lower plate or use a single temperature for both platens. This function makes it easy to obtain even better splice results for belt materials with a fabric inlay or coating.

Unique programming features enable a more precise setting of the dwell time (down to seconds), an automatic dwell time countdown and a preheating cycle. A controlled - stepped - preheating will provide better splice results with thicker or less heat conducting belt materials.

The splice platens have integrated cool zones on both sides of the heating zone, This will result in ultra smooth splices even for the most difficult belt materials. No inlays of glass fibre or stainless steel are used which may cause pressure differences. The applied pressure will be the same at any point of the splicing plate. This design results in:

With conventional systems these malformations are often difficult to control and will require possible process adjustments, trial runs and a lot of craftsmanship. However, the Aero™ can be operated with minimal training. With the right predefined settings the unit generates repeatable, high quality splices time after time.

Item # |

Effective Length |

Effective Width |

Weight Lower Part |

Weight Upper Part |

Total Weight |

List Price |

|---|---|---|---|---|---|---|

| Aero 300 | N/A 12 in305 mm | N/A 5.1 in130 mm | N/A 22 lbs10 kg | N/A 24 lbs11 kg | N/A 46 lbs21 kg | QUOTE |

| Aero 600 | N/A 24 in610 mm | N/A 5.1 in130 mm | N/A 33 lbs15 kg | N/A 33 lbs15 kg | N/A 66 lbs30 kg | QUOTE |

| Aero 900 | N/A 36 in914 mm | N/A 5.1 in130 mm | N/A 44 lbs20 kg | N/A 40 lbs18 kg | N/A 84 lbs38 kg | QUOTE |

| Aero 1200 | N/A 48 in1219 mm | N/A 5.1 in130 mm | N/A 55 lbs25 kg | N/A 48 lbs22 kg | N/A 104 lbs47 kg | QUOTE |

| Aero 1500 | N/A 60 in1524 mm | N/A 5.1 in130 mm | N/A 66 lbs30 kg | N/A 57 lbs28 kg | N/A 123 lbs56 kg | QUOTE |