| Items |

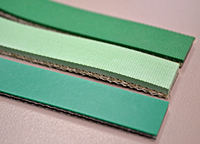

HAB-12E

High Duty Conveyor & Processing Belts

|

HAG-12E

High Duty Conveyor & Processing Belts

|

HAL-12E

High Duty Conveyor & Processing Belts

|

HAR-12E

High Duty Conveyor & Processing Belts

|

HAT-12P

High Duty Conveyor & Processing Belts

|

|

Thickness

|

N/A

2.0 mm0.08 in

|

N/A

5.8 mm0.23 in

|

N/A

2.5 mm0.1 in

|

N/A

1.9 mm0.07 in

|

N/A

3.0 mm0.12 in

|

|

Mass of Belt (Belt Weight)

|

N/A

2.4 kg/m²0.49 lbs/ft²

|

N/A

4.6 kg/m²0.94 lbs/ft²

|

N/A

2.5 kg/m²0.51 lbs/ft²

|

N/A

1.8 kg/m²0.37 lbs/ft²

|

N/A

3.2 kg/m²0.66 lbs/ft²

|

|

Min. Nosebar Radius

|

N/A

|

|

Min. Pulley Diameter

|

N/A

60 mm2.4 in

|

N/A

80 mm3.1 in

|

N/A

48 mm1.9 in

|

N/A

40 mm1.6 in

|

N/A

40 mm1.6 in

|

|

Min. Pulley Diameter with Counter Flection

|

N/A

70 mm2.8 in

|

N/A

100 mm4 in

|

N/A

60 mm2.4 in

|

N/A

50 mm2 in

|

N/A

50 mm2 in

|

|

Tensile Force for 1% Elongation (k1% Static) per unit of Width (Habasit Standard SOP3-155 / EN ISO 21181)

|

N/A

23 N/mm131 lbs/in

|

N/A

19 N/mm108 lbs/in

|

N/A

21 N/mm120 lbs/in

|

N/A

21 N/mm120 lbs/in

|

N/A

7.5 N/mm43 lbs/in

|

|

Tensile Force for 1% Elongation (k1% Static) per unit of Width (Habasit Standard SOP3-064)

|

N/A

|

|

Tensile Force for 1% Elongation after Relaxation (k1 % relaxed) per unit of Width (Habasit Standard SOP3-155 / EN ISO 21181)

|

N/A

15 N/mm86 lbs/in

|

N/A

13 N/mm74 lbs/in

|

N/A

14 N/mm80 lbs/in

|

N/A

14 N/mm80 lbs/in

|

N/A

3.2 N/mm18 lbs/in

|

|

Admissible Tensile Force per unit of Width

|

N/A

20 N/mm114 lbs/in

|

|

Min. Continuous Operating Temperature Admissible

|

N/A

0 ºC32 ºF

|

N/A

0 ºC32 ºF

|

N/A

-30 ºC-22 ºF

|

N/A

-20 ºC-4 ºF

|

N/A

0 ºC32 ºF

|

|

Max. Continuous Operating Temperature Admissible

|

N/A

100 ºC212 ºF

|

|

Coefficient of Friction on Slider Bed of Pickled Steel Sheet

|

N/A

0.20

|

|

Seamless Manufacturing Width

|

N/A

2400 mm94 in

|

N/A

1200 mm47 in

|

N/A

1200 mm47 in

|

N/A

2400 mm94 in

|

N/A

2400 mm94 in

|

|

Product Group

|

N/A

High Duty Conveyor and Processing Belts

|

|

Product Sub-Group

|

N/A

Rubber Conveyor and Processing Belts

|

|

Main Industry Segments

|

N/A

Materials Handling Mechanical/apparatus engineering Metal working Wood

|

N/A

Materials Handling Packaging Paper converting Paper manufacturing and processing Wood

|

N/A

Materials Handling Packaging Paper manufacturing and processing Wood

|

N/A

Materials Handling Packaging Paper converting Paper manufacturing and processing

|

N/A

Materials Handling Packaging Paper manufacturing and processing Wood

|

|

Belt Applications

|

N/A

Acceleration belt General conveying belt Packaging belt Processing belt

|

N/A

Decline belt General conveying belt Incline belt Paper handling belt Processing belt

|

N/A

Acceleration belt Decline belt General conveying belt Incline belt Paper handling belt

|

N/A

General conveying belt Paper handling belt Power turn belt

|

N/A

General conveying belt Paper handling belt

|

|

Special Features

|

N/A

Abrasion resistant Oil resistant Super adhesive surface

|

N/A

Abrasion resistant Chemical resistant Constant coefficient of friction High coefficient of friction surface Oil resistant

|

N/A

Constant coefficient of friction Temperature variation resistant

|

N/A

Abrasion resistant Chemical resistant Constant coefficient of friction High coefficient of friction surface Oil resistant Powerturn suitable

|

N/A

Abrasion resistant Constant coefficient of friction High coefficient of friction surface Oil resistant

|

|

Mode of Use/Conveyance

|

N/A

Acceleration Declined Horizontal Inclined

|

N/A

Declined Horizontal Inclined

|

N/A

Declined Horizontal Inclined

|

N/A

Declined Horizontal Inclined

|

N/A

Declined Horizontal Inclined

|

|

Conveying Side (Material)

|

N/A

Acrylonitrile-Butadiene-Rubber (NBR)

|

N/A

Acrylonitrile-Butadiene-Rubber (NBR)

|

N/A

Rubber (EPDM)

|

N/A

Acrylonitrile-Butadiene-Rubber (NBR)

|

N/A

Acrylonitrile-Butadiene-Rubber (NBR)

|

|

Conveying Side (Surface)

|

N/A

Smooth

|

N/A

Grip structure

|

N/A

Longitudinal groove structure

|

N/A

Rough textile structure

|

N/A

Rough textile structure

|

|

Conveying Side (Property)

|

N/A

Super-adhesive

|

N/A

Adhesive

|

N/A

Super-adhesive

|

N/A

Adhesive

|

N/A

Adhesive

|

|

Conveying Side (Color)

|

N/A

Green (Habasit green)

|

N/A

Green

|

N/A

Green

|

N/A

Green

|

N/A

Green

|

|

Traction Layer (Material)

|

N/A

Polyester (PET)

|

N/A

Polyester (PET)

|

N/A

Polyester (PET)

|

N/A

Polyester (PET)

|

N/A

Polyamide (PA)

|

|

Number of Fabrics

|

N/A

2

|

N/A

2

|

N/A

2

|

N/A

2

|

N/A

3

|

|

Running Side/Pulley Side (Material)

|

N/A

Polyurethane cross-linked (PUR)

|

N/A

Polyurethane cross-linked (PUR)

|

N/A

Polyurethane cross-linked (PUR)

|

N/A

Polyester (PET) fabric

|

N/A

Polyurethane cross-linked (PUR)

|

|

Running Side/Pulley Side (Surface)

|

N/A

Impregnated fabric

|

N/A

Impregnated fabric

|

N/A

Impregnated fabric

|

N/A

Fabric

|

N/A

Impregnated fabric

|

|

Running Side/Pulley Side (Color)

|

N/A

Black

|

N/A

Black

|

N/A

Black

|

N/A

White

|

N/A

Black

|

|

Slider Bed Suitable

|

N/A

Yes

|

|

Carrying Rollers Suitable

|

N/A

Yes

|

|

Power Turns, Curved Installations

|

N/A

No

|

N/A

No

|

N/A

No

|

N/A

Yes

|

N/A

No

|

|

Nosebar Suitable

|

N/A

No

|

|

Low Noise Applications

|

N/A

No

|

|

Antistatically Equipped

|

N/A

Yes

|

|

Metal Detector Suitable

|

N/A

No

|

|

Flammability

|

N/A

No specific flammability prevention property

|

|

Food Suitability FDA

|

N/A

No use intended

|

|

Food Suitability USDA

|

N/A

No use intended

|

|

Food Suitability EU

|

N/A

No

|

|

Other Conformance/Approval

|

N/A

JFRL passed

|

N/A

|

N/A

|

N/A

|

N/A

|

|

Notes

|

N/A

All data are approximate values under standard climatic conditions: 23ºC/73ºF, 50% relative humidity (DIN 50005/ISO 554), and are based on the Master Joining Method.

|