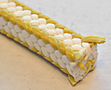

2003 Braided Packing/PTFE Yarn, Aramid Corners

(10)CONSTRUCTION

Style 2003 is an interlock braided packing, using pure PTFE yarn, reinforced with aramid corners. The yarns are pretreated with PTFE dispersion, plus a break-in lubricant to reduce the coefficient of friction, as well as the frictional heat created by high shaft speeds.

APPLICATION/SERVICE

Style 2003 packing, with its unique combination of PTFE and aramid fibers, is dimensionally stable, non-contaminating, has excellent lubricating and running characteristics, and becuase of the aramid corners, is very wear resistant. It handles acids, alkalis, and a broad range of chemicals. It is well sutied for service in rotary and reciprocating pumps, mixers, agitators and reactors, especially where abrasive wear is a problem.

SERVICE LIMITS

Temperature limits

Minimum: -150°F (-100°C)

Maximum: 540°F (280°C)

Pressure limits:

Rotating: 435 psi (30 bar)

Reciprocating: 1450 psi (100 bar)

Static: 2600 psi (180 bar)

Shaft Speed: 2350 fpm (12 m/s)

pH: 2-12

2004 Expanded PTFE/Graphite with Aramid Corners

(12)CONSTRUCTION

Style 2004 is an interlock braided packing using aramid yarn treated with PTFE suspensoid. The packing is also lubricated with a silicon-based compound for quick and easy break-in.

APPLICATION/SERVICE

Style 2004 is an extremely durable packing able to withstand granular and abrasive applications. It is recommended for service in superheated steam, slurries, petroleum derivatives, solvents and liquified gases. It is commonly used in centrifugal, rotary and reciprocating pumps, agitators and mixers, especially in the paper, steel, petroleum and chemical industries, and in sewage treatment plants.

SERVICE LIMITS

Temperature limits

Minimum: -150°F (-100°C)

Maximum: 540°F (280°C)

Pressure limits:

Rotating: 500 psi (35 bar)

Reciprocating: 2900 psi (200 bar)

Static: 3600 psi (250 bar)

Shaft Speed: 2950 fpm (15 m/s)

pH: 2-12

2017 Braided Packing/Aramid Yarn, PTFE Impregnated

(10)CONSTRUCTION

Style 2017 packing is an interlock braid of Teadit's EG2 PTFE/graphite yarn, reinforced with high strength aramid yarns corners. EG2 is formed from expanded PTFE in which fine particles of graphite have been encapusulated. The resulting packing provides good chemical resistance and heat dissipation plus anti-extrusion strength.

APPLICATION/SERVICE

Style 2017 packing can handle a broad range of chemicals in the 3-11 pH range. It is used in papermill stock pumps, agitators, or any service where high strength and good lubricating qualities are needed.

SERVICE LIMITS

Temperature limits

Minimum: -148°F (-100°C)

Maximum: 540°F (280°C)

Pressure limits:

Rotating: 435 psi (30 bar)

Reciprocating: 2900 psi (200 bar)

Static: 2900 psi (200 bar)

Shaft Speed: 3900 fpm (20 m/s)

pH: 2-12

2044 Braided Packing/Spun Aramid Yarn, PTFE Impregnated

(12)CONSTRUCTION

Style 2044 is an interlock braid, using spun aramid carded yarns, treated individually with PTFE suspensoid. The packing is also lubricated with silicone based compound for quick and easy break-in. The use of spun aramid fibers produces a softer and very tough packing, but one that is less abrasive than packings braided with aramid filaments.

APPLICATION/SERVICE

Style 2044 is a durable packing able to withstand granular and abrasive applications. It is recommended for service in superheated steam, slurries, petroleum derivatives, solvents, chemicals, liquified gases, pulp and paper stocks, sugar syrups, and other abrasive fluids.

SERVICE LIMITS

Temperature limits

Minimum: -150°F (-100°C)

Maximum: 540°F (280°C)

Pressure limits:

Rotating: 300 psi (20 bar)

Reciprocating: 1150 psi (80 bar)

Static: 2200 psi (150 bar)

Shaft Speed: 2950 fpm (15 m/s)

pH: 2-12