Belt Fabrication Capabilities

belt-fabrication-capabilities

Please visit our main catalog page of Dunham Rubber Products to see some of the other product line offerings and services available. /Asset/Belt Vulcanizing.jpg

Dunham Rubber offers 24 hour 7 days a week on site belt installation. We work around your maintenance schedule. Call today to schedule your next belt installation. We will show up on time, with the proper equipment to efficiently and accurately have your belt running as quickly as possible. /Asset/Belt Installation.jpg

Belt Slitting Services

Dunham Rubber owns and operates 3 large belt slitters as well as 3 smaller circular slitters. We have the capability of slitting slabs of belt up to 72" wide. Our ability to buy in slab form;- Keeps end user prices down

- Offers greater potential to meet customer needs

- Translates into faster delivery when you the customer must have your line running.

Belt Vulcanizing Services

Dunham Rubber owns 7 large portable presses of various sizes up to 120" wide. Also we have several smaller hand presses for other light duty endless or vulcanized belt applications. We have the capability of making truly endless belts of almost any width in your plant when you need the work done. Call our customer service representatives to set up your next job. Remember we not only vulcanize your belts, we supply belting for almost any application. Our representatives have the knowledge and experience to help make the proper belting selection for your particular application, which saves you both time and money.Please visit our main catalog page of Dunham Rubber Products to see some of the other product line offerings and services available. /Asset/Belt Vulcanizing.jpg

Belt Installation Services

You need your belts installed at 5:00 A.M. Saturday morning, NO PROBLEM!Dunham Rubber offers 24 hour 7 days a week on site belt installation. We work around your maintenance schedule. Call today to schedule your next belt installation. We will show up on time, with the proper equipment to efficiently and accurately have your belt running as quickly as possible. /Asset/Belt Installation.jpg

Endless

(5)- Skived Endless

- Finger Endless

- Finger over Finger Endless

- Lap Endless

- Sewn

V-Guide

- Various sections available:

- K-6

- K-8

- K-10

- K-13

- K-17

- A-Modified

- A-Section

- B-Section

- C-Section

- K-22

- Available in:

- PVC

- Rubber

- Urethane

- Solid or Notched

- Single/Multiple Guides

Cleating

- Available In:

- Molded Rubber

- PVC T-Cleat

- Rubber T-Cleat

- Lug Cleat

- V-Guide Cleat (PVC & Rubber)

- Square Cleat (PVC & Rubber)

- Bolt-On Cleat

- Full Width, Indent, Center Gap, and Centers per Instruction

Sidewalls

- Available in Rubber Corrugated, PVC Corrugated, and Urethane Corrugated

- Gum Drop Edging

- PVC and Urethane Straight

- Available-Solid, Siped, Indents, per Drawing

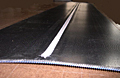

Capped Edges

Capped edge fabrication provides solutions to contamination issues, frayed edges and moisture absorption concerns. /Asset/capped edge.jpg

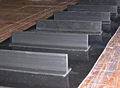

Perforated Belts

Different hole diameters and patterns per print, single rows for folding rail belts. /Asset/Perforated belt.jpg

Special Covers

- Covers available include:

- Rubber

- Foam

- Leather

- Heat Resistant

- Urethane

- Sponge

- In various thicknesses

Spiral Link

- 150 P.I.W. Rating

- Available in:

- Smooth carboxylated nitrile

- Rough top carboxylated nitrile

- Brown nitrile rough top

- Gum rough top

- Tan diamond top

- White tyler wire

- Black smooth MOR

- White smooth nitrile

- Polyolefin

- Silicone

- No metal lacing

- V-Guiding available

- Field repair easily done

- Used in magnetic conveyors and weigh scales

Laced Belts

Clipper & Flexco:- Steel

- Stainless Steel

- Recessed

- Hidden

- Flap over

- Plastic (Spiral & Rivet)